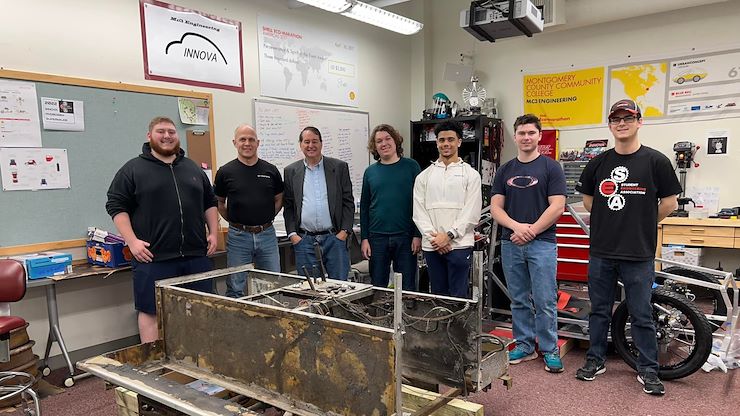

Engineering students are working on upgrading a rail speeder for Colebrookdale Railroad's rail bike program. They have been asked to replace its combustion-powered drive system with a new electric one. Photo courtesy of Colebrookdale Railroad.

Engineering students at Montgomery County Community College are working on a unique, environmentally friendly project that is set to benefit Colebrookdale Railroad and the community.

Students have been tasked with updating a nearly 70-year-old railroad speeder for the 21st century. In addition to upgrading some of the vehicle’s structural elements, they have been asked to replace its combustion-powered drive system with a new electric one. The speeder will be put back into service for the first time in years after the work is complete and will support the Colebrookdale Railroad’s community railbike tour program.

“It was gas-powered and needed to be turned around to effectively operate in the opposite direction,” said William Brownlowe, Professor of Engineering. “Now it will be electric and will run in both directions without being rotated.”

‘A working beast’

Before being replaced by more modern rail vehicles, rail speeders were originally

put into service to transport up to six crew members quickly up and down rail lines

and inspect the tracks, according to the North American Rail Car Operators Association (NARCOA). Slower than a train or car, the small box-shaped vehicles get their name

because they’re faster than a hand-powered vehicle like a handcar.

Before being replaced by more modern rail vehicles, rail speeders were originally

put into service to transport up to six crew members quickly up and down rail lines

and inspect the tracks, according to the North American Rail Car Operators Association (NARCOA). Slower than a train or car, the small box-shaped vehicles get their name

because they’re faster than a hand-powered vehicle like a handcar.

For the past eight years, Colebrookdale Railroad has hosted the Secret Valley Excursions Railbike tours, which allow visitors to ride along the rail lines outdoors while sitting in pedal carts. Riders travel a four-mile journey that begins and ends in Pottstown. The program uses a speeder to tow the railbikes back to the station, respond to emergencies, and inspect the track for debris.

However, Michele Barrett, Director of Educational Programs at Colebrookdale Railroad, who heads the Secret Valley Excursions program, said guests expect a quiet adventure when they’re riding a railbike and the speeder they use is too noisy.

“The speeder is a working beast, but they are not quiet,” said Barrett. “Another hindrance beyond the noise was that speeders are meant to go faster and pull heavier weight. The work it was required to do for the railbike program was too slow and we would apply the brake too much. It was not being used for its original purpose.”

Additional problems with the speeder were its weight and its inability to travel effectively

in both directions without turning. A speeder weighs about a ton, which was a problem

for Barrett and her employees at Secret Valley Excursions. Since a speeder at times

needs to be revered on the track, the staff would have trouble finding a way to lift

it up. Plus adding a turntable to the already heavy vehicle to allow it to travel

in both directions would add more weight.

Additional problems with the speeder were its weight and its inability to travel effectively

in both directions without turning. A speeder weighs about a ton, which was a problem

for Barrett and her employees at Secret Valley Excursions. Since a speeder at times

needs to be revered on the track, the staff would have trouble finding a way to lift

it up. Plus adding a turntable to the already heavy vehicle to allow it to travel

in both directions would add more weight.

“My staff is a great committed core group of teenagers and folks on the autism spectrum,” she said. “Nobody is bench pressing massive weight.”

An ideal student project

In addition to the problems with its speeder, Colebrookdale Railroad was also looking

to update its fleet of railbikes, too, to include electric motors, so riders could

get some assistance as they pedaled up and down the tracks. Colebrookdale Railroad

reached out to area schools to see if any were interested in helping upgrade the rail

bikes fleet.

In addition to the problems with its speeder, Colebrookdale Railroad was also looking

to update its fleet of railbikes, too, to include electric motors, so riders could

get some assistance as they pedaled up and down the tracks. Colebrookdale Railroad

reached out to area schools to see if any were interested in helping upgrade the rail

bikes fleet.

“Perkiomen School said they would help redesign the current railbike fleet with electric propulsion and we said we would redesign the railbike from the ground up,” said Brownlowe. “While I was there looking at their railbikes, Michelle (Barrett) at Colebrookdale Railroad said, ‘You know, there’s this other project that we would like to ask a school to bid on. That’s update our speeder,’ which they use for towing the railbikes and also as an emergency vehicle. ‘We would like to update that to become fully electric.’”

The initial idea was for students at MCCC to pull apart the speeder currently in use at Colebrookdale Railroad and convert it to an electric vehicle. However, Scott Bentley, CEO of VideoRay, of Pottstown, purchased an old speeder built circa 1953 at an auction and funded the project to restore it.

“It’s from the Woodings Company,” said Bentley, a NARCOA member, and strong financial supporter of Colebrookdale Railroad’s Steel River Train Station. “It was a company in Canada. It was one of three Woodings that we purchased.”

Bentley said he wanted to see the speeder electrified because of the many benefits it would provide.

“I am an owner of Teslas— I have three, two are on order,” he said. “I like electric. Electric is quieter. There are no fumes; it requires a fewer number of natural resources.”

He likes the idea of turning a gas-powered speeder into an electric vehicle especially

since electric batteries, motors and controllers are becoming better and easier to

acquire. In addition, he wanted to have students at a local school involved in the

project, he said.

He likes the idea of turning a gas-powered speeder into an electric vehicle especially

since electric batteries, motors and controllers are becoming better and easier to

acquire. In addition, he wanted to have students at a local school involved in the

project, he said.

“It’s an ideal student project,” he said. “It’s big enough to be significant and small enough to be done in a semester.”

The chassis of the speeder can be found in the basement of the Science Center on the Blue Bell Campus. Students began by disassembling the vehicle down to its basic steel frame.

“You look at it and go, ‘it’s a shell.’ It wasn’t a shell when we got it,” said Brownlowe. “We had to disassemble it. We had to remove the engine, transmission and all of the supporting framework.”

Mechanical Engineering Science major Jonah Oberman, 19, of Abington, is in his second semester at MCCC and is one of the students currently working on the extracurricular project.

“So far it’s been pretty fun,” he said. “When they brought it in and put it on a forklift, we gently maneuvered it into the lab and deconstructed it to get step-by-step pictures of the disassembly. We cleaned it out, removing all the foam. I wasn’t here when they took out the engine and the transmission, but overall, we did it pretty quickly, in like a matter of a week or two. We deconstructed it and returned the shell for repurposing.”

There’s still a lot of work to be done, said Brownlowe, to get the speeder back up and running. COVID-19 protocols slowed down progress on the project, but the goal is to get it finished as quickly as possible.

“We have to sandblast the whole thing,” he said. “Once we’re done sandblasting, we’re going to buy some aluminum and start building back some of the structural aspects of it. We have to convert the rear trans axel, which has a drive shaft right now. We have to convert that to a drive shaft with a belt sprocket, so you can drive it with a motor. We’re using an easy go - it’s like a golf cart but it’s really a car. It’s low-speed vehicle. We’re going to put that onto the vehicle.”

Oberman said he wants to study automotive design someday, so the project has been right up his alley. He’s excited to see the project come to completion.

“Overall, it’s been fun,” he said. “We’ve learned a little bit about it. We were like ‘Wow’ we couldn’t believe it was this old and still holding together. I know I’m excited to get back into this project, because I love the idea of the restoration of old vehicles and making them new. I like the idea of taking something as old as this that was once used and now is forgotten, to be brought back in and used again. With something new and modern being electric, hopefully we can make it as perfect as we possibly can.”