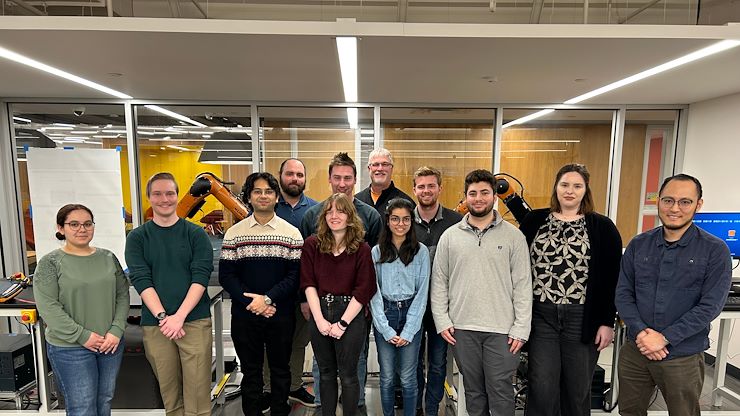

Montgomery County Community College Engineering and Computer Science students participated in the Automation Innovation Challenge by Merck & Co., which put their skills in robotics and computer programming to the test. Photos by Eric Devlin

Eight Montgomery County Community College Engineering and Computer Science students took part in the Automation Innovation Challenge sponsored by Merck & Co. recently.

Students Ruby Armor, Gargi Donde, Jake Hamburg, Muhammad Haris, Intizor Hoshimova, Thomas Quinn, David Siegfried and Matt Signorelli put their skills in robotics and computer programming to the test during the event, which ran Nov. 22, 23, 25 and 26 in the Engineering Lab of the Science Center on the College’s Blue Bell Campus.

Working as a team, students were presented with a real-world problem and given training, tools and industry mentors necessary to solve it.

“This year, the challenge is based on a chemical manufacturing company,” said Scott

Ziegler, Director, Scientific Automation at Merck. He oversaw the project with Merck

employees Erin Coppola, Scientist, Biology-Discovery Engineering and Noah Holihan,

Senior Scientist, Scientific Automation, as well as MCCC faculty members Chengyang

Wang, Ph.D., Associate Professor of Engineering, and Kendall Martin, Ph.D., Professor

of Computer Science.

“This year, the challenge is based on a chemical manufacturing company,” said Scott

Ziegler, Director, Scientific Automation at Merck. He oversaw the project with Merck

employees Erin Coppola, Scientist, Biology-Discovery Engineering and Noah Holihan,

Senior Scientist, Scientific Automation, as well as MCCC faculty members Chengyang

Wang, Ph.D., Associate Professor of Engineering, and Kendall Martin, Ph.D., Professor

of Computer Science.

The premise of the challenge said students worked as employees at the ‘Monty Chemical Company,’ and there was a breakdown of the manufacturing system for the chemical ‘Montcopomene.’ Instead of receiving a bottle every hour, students received 64 bottles at the end of the week. They were tasked with creating a proof-of-concept automation system using Kuka six-axis industrial robots and a variety of other equipment.

“In the chemical manufacturing process, when they are filling containers or bottles, from a quality control perspective, they would pull samples and test the samples. One of the tests you would do is measuring your fill volume to make sure that what you said to put in the bottle is what is actually getting put in the bottle. These guys are building the quality control process.”

With one of the Kuka robots, students were tasked with sorting the bottles into batches,

based on a manifest they were provided. They then had to transfer the bottles to an

associated caddy for that particular batch and transfer them to a conveyor belt that

leads to a second Kuka robotic arm to process the individual bottles. Meanwhile the

computer control system then had to manage the data taken from a robotic arm and compare

it to the information on the manifest. Students lastly had to perform a data analysis.

With one of the Kuka robots, students were tasked with sorting the bottles into batches,

based on a manifest they were provided. They then had to transfer the bottles to an

associated caddy for that particular batch and transfer them to a conveyor belt that

leads to a second Kuka robotic arm to process the individual bottles. Meanwhile the

computer control system then had to manage the data taken from a robotic arm and compare

it to the information on the manifest. Students lastly had to perform a data analysis.

“The data is rigged,” said Ziegler. “There are trends. There are situations where the first four bottles are really good and then the volume goes way down. So, what happened? Well, the nozzle probably clogged or something. So, they’ll have to answer things like that. Part of that is looking at the data, answering questions, doing data science and analysis.”

Included in the analysis is the financial perspective, said Ziegler.

“If it costs X number of dollars per gram, and we’re overfilling by 10 percent, the company’s losing money,” he said.

Combining their Computer Science and Engineering strengths, students worked together

to write the necessary software, run the robotic arm, run a full production line and

analyze the data. Then they gave a formal presentation to Merck and MCCC employees

where they talked about some of the technical challenges they faced and ultimately

how they were able to complete the task by leaning on each other’s strengths.

Combining their Computer Science and Engineering strengths, students worked together

to write the necessary software, run the robotic arm, run a full production line and

analyze the data. Then they gave a formal presentation to Merck and MCCC employees

where they talked about some of the technical challenges they faced and ultimately

how they were able to complete the task by leaning on each other’s strengths.

Students said they enjoyed the Merck Challenge because it felt like a real problem they may soon face in the near future. Computer Science major Muhammad Haris thought it was a wonderful opportunity, especially for students at a community college level.

“Being a part of this challenge not only gives you the confidence you are a problem solver it gives you the confidence to present, and it gives you the skills to work alongside a team,” he said. “It gives you the skills to learn how to integrate two different parts of a project, the engineering part of the project and the programming part of the project because in real-life situations in companies, all the different aspects of a project integrate.”

Computer Science major Intizor Hoshimova appreciated the chance to begin to understand what the real world will soon feel like.

“This is a great opportunity for students to come and see what they can be doing in the future with their majors, and I think that will help them understand and learn how to work with other departments because when you are in a situation like this you are not just with a bunch of programmers, you are with engineers and other people in the company,” said Hoshimova. “It also helps with higher-level thinking. We think about errors, which is not something we’re taught – the different errors and things you can run into. I think it is a great opportunity, and I would like to thank MCCC and Merck for this opportunity.”

Mechanical Engineering major Ruby Armor, who previously worked on the Project INNOVA hydrogen fuel-cell urban concept car, said the Merck Challenge had a bit of a learning curve.

“It’s been very rewarding to make it do the thing it’s supposed to do without really knowing anything before this. I kind of just jumped into it,” she said. “We’re all involved in INNOVA (with Thomas Quinn, Matt Signorelli and Jake Hamburg). We’re maxing out the hands-on experiences that Montco offers. The classes are one thing, but this puts it all together.”

Jake Hamburg, an Electrical Engineering major, said he has previous experience in both Engineering and Computer Science, so the project felt like a great mesh of both worlds.

“That’s what computer engineering is – half hardware, half software, so I know the engineering side of it and the software side of it,” he said. “It’s really great seeing your code actually doing something. There are few instances where my code has been doing something physically. This is really an opportunity you can’t get in other places.”